3020 Raymond Courier Automated Tow Tractor

-

Return on Investment

By redeploying personnel to optimize productivity, Raymond Courier Trucks offer an industry-leading ROI under 24 months.*Return on Investment -

Flexibility

-

Scalable Solution

-

Low Clearance Arch (optional)

For applications that operate under low overhanging structures with a 63" minimum clearance.Low Clearance Arch (optional) -

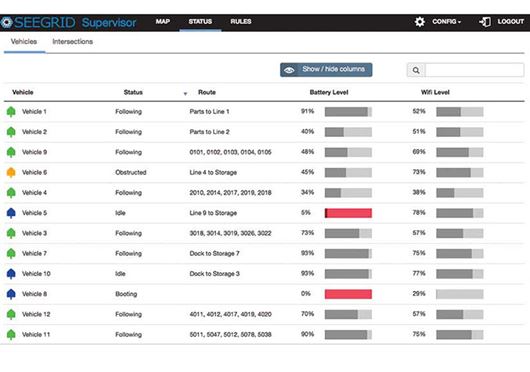

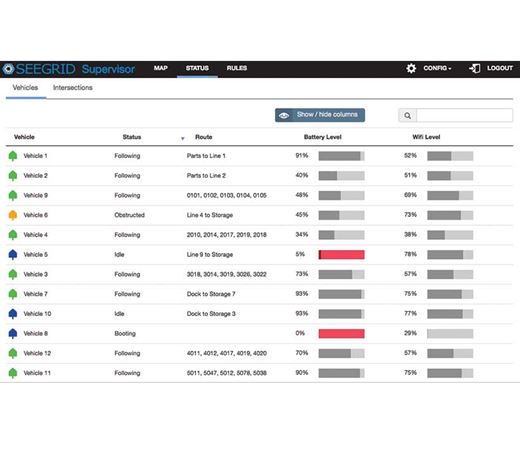

Fleet Management Application

The web-based Supervisor software monitors, controls and provides real-time vehicle data.Fleet Management Application

Simplicity, for Productivity's Sake

Boost productivity in batch picking, cart towing and parts-to-line operations with the Raymond Courier automated tow tractor. It makes simple work of automating repetitive and time-consuming hauls that are labor intensive but don't require skilled attention from an operator.

- Battery: 24 volt

- Capacity: 10,000 lbs.

- Max Ramp Elevation/Incline: 5% at 500 lbs.

-

3020 Low Clearance Arch

For applications that operate under low overhanging structures (conveyors, stairwells, and facility infrastructure such as piping, tubing, and mezzanines).

+ Floor to Top of Operator User Interface: 63”

+ New light curtain design: 2 SICK-TIM sensors for extended coverage

Built to Perform

-

Automated Forklifts – Consistent, Productive Operation

With a continuing shortage of skilled labor and rising labor costs, Raymond is committed to providing the solutions you need to optimize your warehousing operations. The Raymond Courier brings all the benefits of automation to the most trusted forklifts on the market. With easy implementation, simple operation, and remote management capabilities, our autonomous forklifts offer the perfect entry point into automation. -

Giant Eagle: Improving Productivity with Flexible Automation

Incorporating Raymond Courier driverless forklift vehicles into their warehouse, Giant Eagle in Pittsburgh, PA, reduced the amount of touches and time travel in their warehouse facility. Specifically in the put-away function, a task where travel has taken 4 minutes to go from point A to point B has been reduced to 2 min—an improvement of 40-50% on each haul. -

Boeing Utilizes Automatic Forklifts to Streamline Manufacturing

See how Raymond Courier driverless forklifts deliver parts to 787 mechanics at the Boeing factory in Everett, Washington.

-

Dispatch

Operator use the operator interface to identify the start, drop and end locations for the route. Operators then press the green start button to dispatch the truck on a selected route.

-

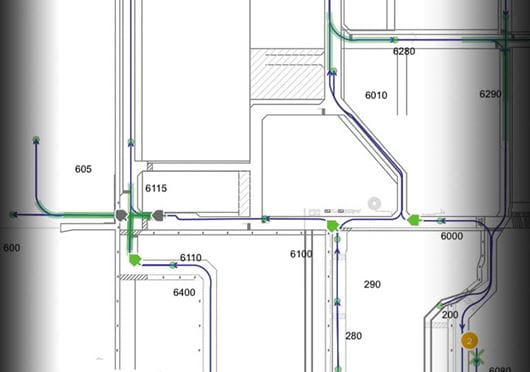

Localization

The navigation system on the Raymond Courier compares visual and odometry data, such as steering angle and speed, with data learned when a route is first programmed.

-

Navigation

Once a truck is dispatched in automated mode, the navigation system calculates the shortest path within the programmed route network.

-

Behaviors

Behaviors that can be programmed into truck routes include pauses, slowing down, horn honks, wait and ramps.

-

Obstructions

The primary obstruction sensor identifies obstructions in a truck's path. If an obstruction is identified in the slow field, the Raymond Courier will reduce travel speed to 1.1 mph. The slow field turns with the truck around corners. If an obstruction is detected within the stop field, the Raymond Courier will come to a stop.

-

Fleet Management

Supervisor software monitors, controls and provides real-time vehicle data through a comprehensive web-based fleet management application accessible from any web-enabled computer or mobile device.

-

Horizontal Transport

Raymond Courier automated lift trucks provide a flexible, cost-effective, automated solution for repeatable horizontal transport tasks. Specific guidelines for each model and capability can be obtained from your local Raymond Solutions and Support Center. The 3020 automated tow tractor is suited for distribution and manufacturing operations, including pulling carts or trailer loads in batch picking, parts-to-line- and end-of-aisle (automated conveyor cart) applications.