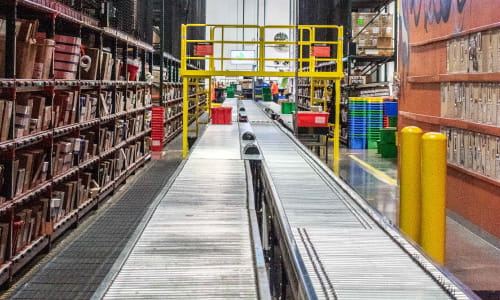

Keep Your Equipment and Business Running

-

With the most comprehensive and responsive conveyor maintenance program in North America, Associated can help you optimize the uptime, performance, and longevity of your equipment. Delivered through our nationwide network of Solutions & Support Centers and their highly trained technicians, the program offers:

With the most comprehensive and responsive conveyor maintenance program in North America, Associated can help you optimize the uptime, performance, and longevity of your equipment. Delivered through our nationwide network of Solutions & Support Centers and their highly trained technicians, the program offers:- + Quick response times

- + Reduced costs

- + Exceptional first-time fix rates

- + Consistent coast-to-coast coverage

Let us take some of the burden off your in-house resources by providing:

-

- Proactive scheduled maintenance to minimize breakdowns

- Assistance with OSHA compliance

- Service history record-keeping

-

- 24/7/365 emergency service

- State-of-the-art dispatching

- Customized service plans

- Broad off-the-shelf parts availability

Our scheduled maintenance program for conveyors includes all

necessary checks, adjustments, and lubrication, including:

necessary checks, adjustments, and lubrication, including:

-

-

- All contractors and switches

- Hardware for looseness

- Photo eye/sensor adjustment

- Hydraulic fittings and hoses for oil leakage

- V-belts and O-rings - tension / wear / alignment

- Check sprockets - wear / set / keyways

- Operation of conveyor

- Oil level in gear box

-

- Inspect belt lacing, tension, tracking

- All lubrication points

- Electrical connections

- Check motors for wear and overall condition

- Roller condition and alignment

- All chains - condition / adjustment / lubricate

- Check reducer oil level and noise

- Safety cut out and switches

ADDITIONAL SERVICES

+ Layout and design

+ Mechanical installation

Real World Solutions. Change The Way You Do Business.

For more information about our Conveyor Maintenance services, please fill out the form below. Once your request is received, one of our sales professionals will contact you to discuss your request.