Why Warehouse Labor Tracking and Management Matters

- share

Data Integration, Part 2.

Labor costs are continually on the rise and every minute of every day is affecting your bottom line.

With labor costs climbing and managers’ challenge to effectively track and manage their labor force complicated by the fact that relevant data often resides in multiple systems, we’re using this series to explore where labor management technology is going. We’re considering the types of useful data available and how to effectively corral and make sense of data to better manage your labor force.

In the first installment we looked at data integration. In this second installment of our three-part series, we are going to examine the different approaches to pulling in data and how creating a labor management system with multiple data sources can create a more effective and efficient warehouse.

WMS data — a limited view

Often, companies begin tracking labor metrics through the use of a warehouse management system (WMS). Although a WMS is a great place to start, it gives you only part of the picture as it relates to your labor force. For example, your pickers are not always scanning, so you are capturing only what they’re doing when they pull the trigger on that RF device. Labor is constantly happening throughout your facility — even if it’s not actively tracked via WMS.

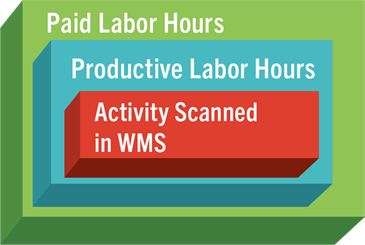

The diagram here is representative of what we typically see in the industry.

- The green box is the total number of labor hours you are paying for, based on the time clock — who is clocked in and for how long, regardless of what they are doing.

- In the second box, the blue box, we see productive labor hours. In most facilities, we see that anywhere between 65% and 75% of total paid hours are productive. However, that also means that 25% to 35% of paid hours are nonproductive. These non-value-added hours, often called “Indirect,” during which you are not able to track what the employee is doing, are essentially what we call a dark area or lost time.

- In the third box — the red box — we see activity scanned into the WMS. This red box comprises only about 40% of the actual paid labor hours. This means that with a WMS alone, you are missing visibility to approximately 60% of the labor hours you are paying for.

Adding data

What’s the point of adding data?

The more data you add, the better you can understand your operation. The real goal moving forward is to have 100% visibility in terms of what your employees are doing as part of the overarching system that you’re running. Adding data gives you that additional visibility. When optimizing labor, it is critical that you get the best data out of your existing systems with the goal of optimizing your labor, because if you can’t track that labor, you can’t understand what your performance baseline is. If you don’t know what your baseline is in terms of performance, how do you know when you’ve gained productivity or when it might make sense to add new technology/systems to your operating environment?

When you optimize your labor tracking using a labor management system (LMS), you gain benefits such as increased margin, cost control, and increased productivity and utilization. You also gain the opportunity to incentivize and recognize your employees through various programs. With LMS, you can optimize your labor planning based on true productivity. Tracking and understanding how people are actually performing can help you develop realistic standards, optimize your systems, and put incentive programs in place.

At that point, you can evaluate whether it makes sense to use people to perform a given task, consider new hardware to help get the job done more efficiently or potentially incorporate an automated alternative. The goal for everyone is to create better service for your end customer. Ultimately, maximizing productivity and adding technology is driving better pricing so you can remain competitive.

Before you take any of these steps, you must understand where you are today. An LMS is critical for understanding what your labor force is doing so you can figure out whether and where it might make sense to invest in technology and/or people.

Stay tuned for our next blog, which will look at integrating technology and labor analytics to tell a more complete story — a way to get more value out of your system and to understand opportunity moving forward.